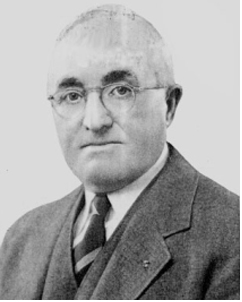

Mr. William Baumbeck

William Baumbeck was born on 5 July

1879 in Germany and immigrated to the United States in 1896. In 1904, he began his civil service career as a

machinist apprentice at Rock Island Arsenal. By the end of World War I, he had been promoted to foreman and was

one of a very few employees with knowledge of the production methods for the highly secret Puteaux Assembly

hydro-pneumatic recoil assembly from the French 75mm field gun. In 1921, Baumbeck was promoted to Superintendent

of the Rock Island Arsenal Manufacturing Department, and in 1926 he was promoted to Civilian-in-Charge of Shop

Operations.

William Baumbeck was born on 5 July

1879 in Germany and immigrated to the United States in 1896. In 1904, he began his civil service career as a

machinist apprentice at Rock Island Arsenal. By the end of World War I, he had been promoted to foreman and was

one of a very few employees with knowledge of the production methods for the highly secret Puteaux Assembly

hydro-pneumatic recoil assembly from the French 75mm field gun. In 1921, Baumbeck was promoted to Superintendent

of the Rock Island Arsenal Manufacturing Department, and in 1926 he was promoted to Civilian-in-Charge of Shop

Operations.

In 1936, Baumbeck began experimenting on broaching methods for rifling barrels. The previous hook cutting method produced an average of only three barrels an hour per machine. Baumbeck developed a method that used a series of progressively larger cutting tools on a single tool. His method rifled 35 barrels an hour per machine. To prove the worthiness of the method, Rock Island Arsenal test fired 8,000 rounds through the broached barrels and the Springfield Armory conducted the same test in 1940. The new method was implemented in Army rifle manufacturing and, subsequently eliminated one of the greatest possible bottlenecks to high volume rifle production at the start of World War II.

During WWII, approximately 155 private manufacturing establishments engaged in the production of war material, and these contracts were negotiated through Baumbeck's office at Rock Island Arsenal. These private companies were given a significant amount of assistance by Baumbeck to rectify their machining and production problems, in obtaining materials and machine tools, and in overcoming numerous difficulties that occurred on a daily basis. Representatives of the contractors visited Baumbeck frequently in order to receive advice and assistance to further the goals of wartime production. With almost all manufacturers, the Arsenal's Production shop furnished cases, drawings of tools, dies, gages, jigs, and fixtures in order to expedite the production for private industry. This close supervision and cooperation between Baumbeck and the local community made possible the high standard of production achieved during World War II. In December 1943, he was recognized for his contributions to the war effort and his dedication to service when he was presented the Emblem for Exceptional Service, the highest War Department award for civilians during World War II.

During World War II, Baumbeck supervised 10,750 men and women throughout the Manufacturing Department during the peak of wartime production. He managed sixteen shops covering a total floor space of 2,389,700 square feet with approximately 5,000 machine tools in operation. Rock Island Arsenal wartime production consisted of various artillery carriages, recoil mechanisms, gun mounts, breech mechanisms, equilibrators for 155mm guns and 8-inch howitzers, optical instruments, machine guns, .30 caliber machine gun barrels, parachutes for air-dropping supplies and equipment from airplanes, metal belt links for .30 and .50 caliber ammunition, and tanks vehicles, as well as great quantities of spare parts for a host of ordnance materiel used in the war.

William Baumbeck retired in 1949, after 44 years of service. He died 4 April 1955.